As the impact of the epidemic continues, enterprises are gradually resuming work, and the impact on the manufacturing industry is gradually becoming apparent: enterprises are facing a series of problems such as delayed construction, personnel isolation, logistics shutdowns, short-term production capacity losses and supply chain tension, as well as production stoppages. More manufacturing enterprises are starting to think about how to transform and upgrade digitalization and intelligence, and intelligent manufacturing is once again on the agenda. At this time, enterprises operating as intelligent factories or "unmanned" factories can quickly resume work after receiving a request to resume work. Fully automated production, remote monitoring equipment and production operations, as well as AGV transportation of materials in the factory area, fully meet the production needs of enterprises during the epidemic period!

As a service provider for enterprise informatization solutions, SiE Information places particular emphasis on technological research and development in the field of intelligent manufacturing. Its independently developed SMOM system will effectively help enterprises affected by the epidemic to resume work smoothly. Help enterprises strengthen their confidence in the "epidemic war", strengthen measures, orderly resume work and production, turn crises into opportunities, and help enterprises build intelligent chemical plants!

The system is rapidly deployed and has a wide range of applications, customizing personalized intelligent chemical plants for you!

SMOM can provide enterprises with efficient and high-quality application platforms, modularizing and serving various business systems, improving the ability of independent development, design, and operation of multi business systems, shortening development time for enterprises, and reducing the cost of enterprise information system construction. A technology platform based on industry solutions that deeply integrates the characteristics and attributes of multiple industries, covering various industries such as electronics, home appliances, furniture, equipment machinery, and photovoltaic. It provides technology and customized services that adapt to enterprise development, and provides full process manufacturing operation management solutions for various industries.

Rich in functions, meeting the business needs of factories for digital production, and starting work more leisurely after the epidemic

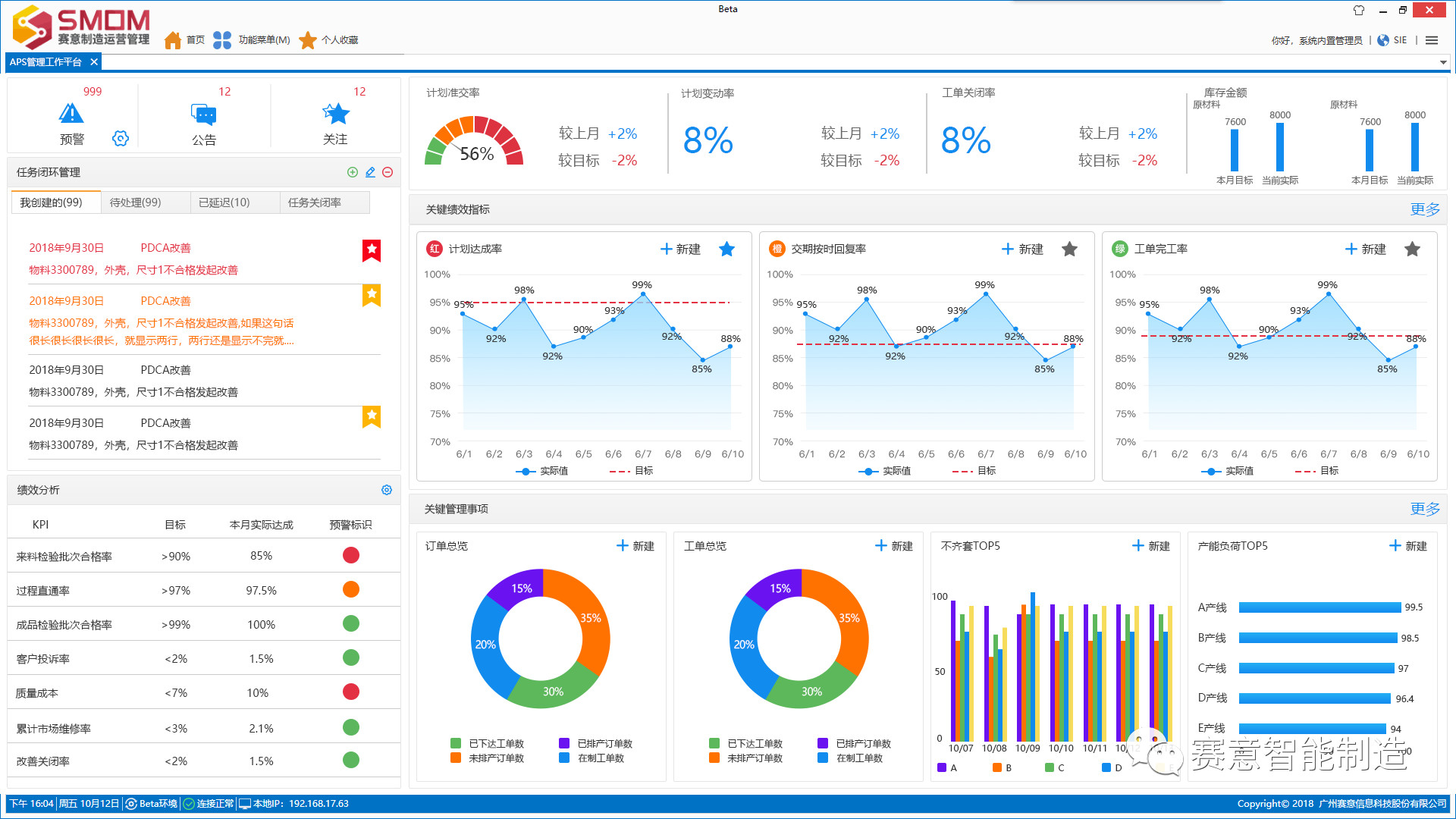

SMOM is a fully customized intelligent manufacturing system designed for manufacturing enterprises. It can provide enterprises with an information-based solution that integrates supplier collaboration portal, internal planning collaboration platform, production and manufacturing execution management platform, automated data collection, equipment integration and monitoring management, full process product information traceability, and intelligent operation management. ↓↓↓↓

1. Flexible production planning and shortened delivery time

The epidemic may lead to a large backlog of orders. How to quickly grasp the current order situation, arrange production reasonably, and ensure customer delivery is the first problem faced after resuming work. How to quickly arrange production plans? The SiE Advanced Planning and Scheduling System SAPS can achieve statistical analysis of massive order data, real-time query of order production progress, traceability to each person, equipment, and material, and early warning of overdue orders.

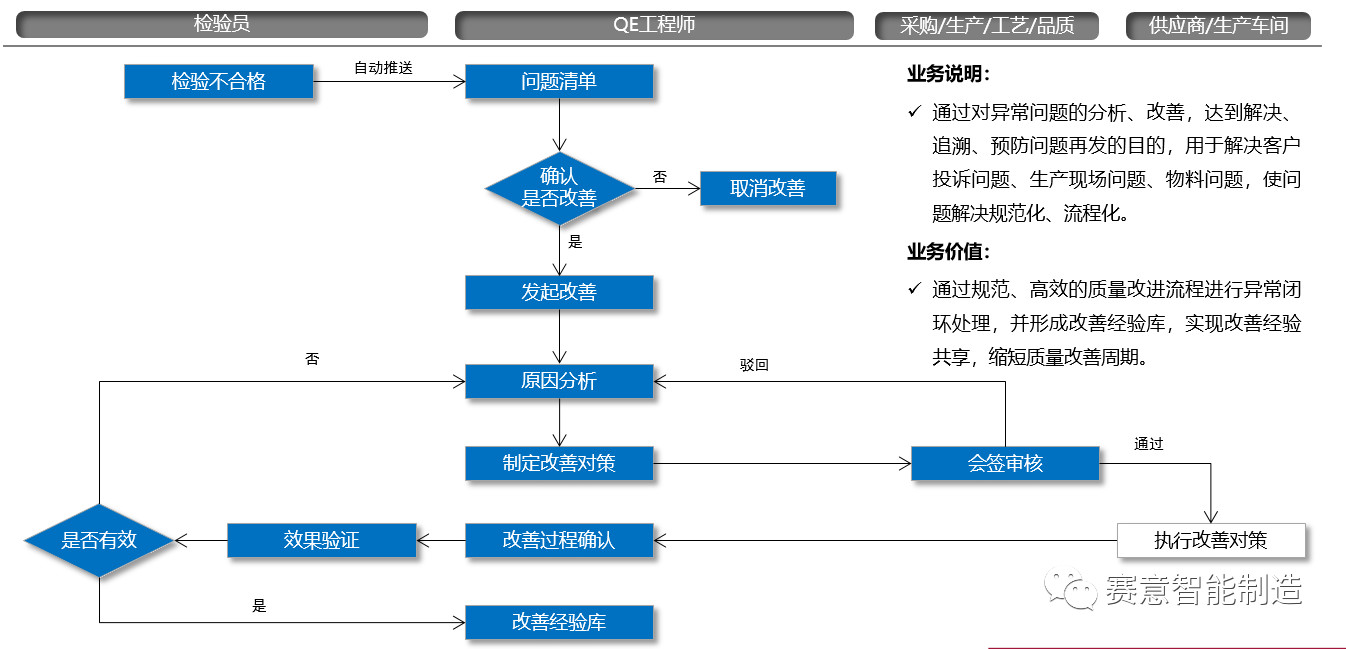

2. Rapid and efficient intelligent control, continuously improving product quality

Protective clothing, masks, etc. play a crucial role in epidemic prevention and can be considered as talismans for life safety! Only qualified protective masks and clothing can provide effective protection. Unqualified protective equipment can only have the opposite effect, so the safety and quality of products are particularly crucial. At this time, the production quality control of enterprises also rings an alarm. The SiE Quality Management System SQMS is based on the idea of continuous improvement in PDCA, which can achieve closed-loop management of abnormal problems, share improvement experience, and continuously improve product quality through continuous improvement in R&D quality, supplier quality, and process quality.

3. Real time control and tracking of production progress, transparent production process

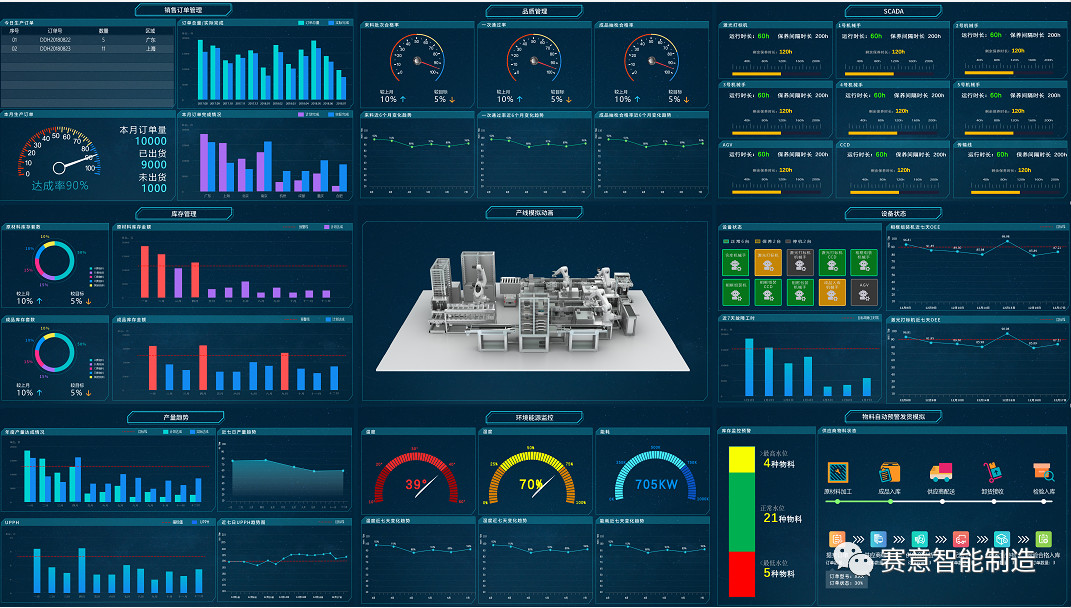

Due to the impact of the epidemic, there is a shortage of manpower on the production line after resuming work. How can we improve production efficiency quickly while also achieving quantitative control of production costs? The SMES production management system can comprehensively collect production progress and real-time production data from workshops through functions such as plan management, production management, and quality management. It can also conduct real-time analysis of production quality yield, plan achievement rate, and team efficiency, track and grasp production status and progress in real time, and achieve transparent workshops for enterprises.

4. SWMS full supply chain intelligent management, optimizing resource utilization

During the epidemic prevention period, the continuous and large-scale prevention and control measures have brought increasing pressure on material demand, especially in the production and manufacturing industries represented by medical consumables, protective equipment, and other medical manufacturing industries, where product production and delivery are not timely enough to keep up with demand. The SiE Warehouse Management System SWMS effectively optimizes the utilization of warehouse resources, flexibly allocates resources, and improves operational efficiency through diversified automatic execution methods and intelligent strategy definitions.

5. SMI has a comprehensive grasp of production data to achieve controllable risks

The SiE Intelligent Operation System SMI helps enterprises establish a scientific business information monitoring system, efficiently applies various data models for business decision-making analysis, and various production indicators are driven by data. Through a scenario based integrated interface and rich graphical elements, it reflects the most real situation on the production site in real time. During the epidemic, managers can remotely monitor and manage online decisions through PC and mobiles devices, effectively and quickly respond to market changes, break geographical restrictions, and make cross regional and cross factory monitoring of the entire production process a reality!

6. Real time data collection, understanding of equipment conditions, and achieving unmanned monitoring

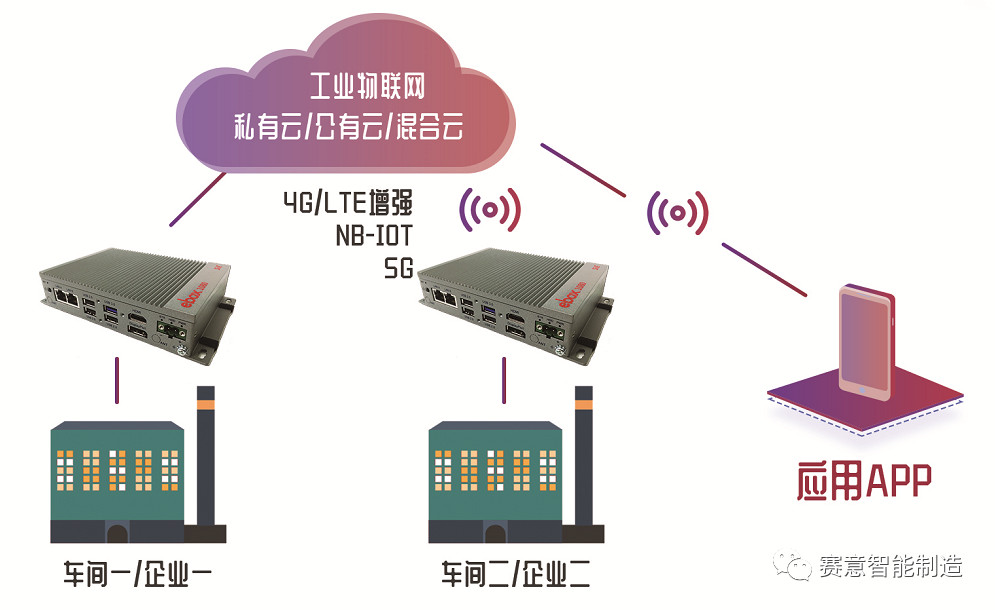

The SiE Manufacturing Digital Interconnection System SMDC connects devices through a data collection platform and provides operational monitoring, data cloud access, data analysis, and visual signage services. It creates an integrated information service platform for users to control and improve the efficiency of vertical collaborative development of enterprises. This way, managers can understand the status of equipment in real-time, achieve remote diagnosis, and effectively reduce personnel attendance during the epidemic, making it a "good assistant" for achieving digital unmanned workshops!

Under the epidemic, we worked together to overcome difficulties in all walks of life. Apart from the epidemic, this "anti epidemic war" has brought new thinking and direction to the development of the manufacturing industry, driving enterprises to transform towards intelligence and automation. In the face of the development needs of enterprises, SiE Intelligent Manufacturing will tirelessly research and develop more products, provide efficient and convenient intelligent services, and better assume social responsibility in the future.

Free access to enterprise production solutions during the epidemic:

Jointly fighting the epidemic, SiE Intelligent Manufacturing provides remote online "pulse diagnosis" for production problems of customer enterprises! In response to the production pain points of enterprises during the epidemic, SiE Intelligent Manufacturing can provide free solutions for enterprises. By scanning the following QR code, you can arrange professional SiE Intelligent Manufacturing Planner to "solve problems" for your enterprise and assist in rapid resumption of work!

Scan the QR code to obtain free enterprise production solutions

They also chose SiE

MATSUSHITA Environmental

阅读更多

Xiaoxiong Electric Appliances

阅读更多

Dongjian Automobiles

阅读更多

Helping you with digital transformation and upgrading

SQMS Quality Management System

SMES SiE Production Execution Management System

SMOM Manufacturing Operations Management Platform